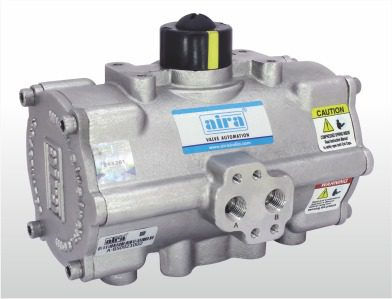

Choosing The Right 90 Degree Pneumatic Rotary Actuator for Your Application

- Aira Euro Automation

- Jun 26, 2023

- 3 min read

Are you in the market for a 90-degree pneumatic rotary actuator? Choosing the right actuator for your specific application is crucial to ensure optimal performance and efficiency. With so many options available, it can be overwhelming to make the right decision. In this article, we will guide you through the process of selecting the ideal 90-degree pneumatic rotary actuator for your needs. Let's dive in!

Pneumatic rotary actuators play a crucial role in various industrial applications, enabling controlled rotational motion. They are widely used in industries such as manufacturing, automotive, aerospace, and more. A 90 degree pneumatic rotary actuator is specifically designed to provide rotational movement within a 90-degree angle. To ensure optimal performance and efficiency, it is essential to select the right actuator based on your specific application requirements.

Understanding Pneumatic Rotary Actuators

Before diving into the selection process, let's gain a basic understanding of pneumatic rotary actuators. These devices convert compressed air energy into rotational motion, allowing for precise control and automation in various applications. Pneumatic actuators are favored for their reliability, simplicity, and cost-effectiveness. They are commonly used in situations where high force and speed are required.

Factors to Consider When Choosing a 90 Degree Pneumatic Rotary Actuator

When selecting a 90-degree pneumatic rotary actuator, several crucial factors need to be considered. Let's explore these factors in detail:

Operating Pressure

The operating pressure of the actuator should align with your system's requirements. Ensure that the actuator can handle the maximum pressure of your pneumatic system without compromising its performance or safety.

Torque Output

The torque output determines the actuator's ability to rotate a load. Consider the required torque for your application and choose an actuator that can provide sufficient torque to meet your needs.

Rotation Speed

The rotation speed of the actuator is vital for achieving the desired performance. Depending on your application, you may require a faster or slower rotation speed. Select an actuator that can deliver the appropriate rotational speed for your specific requirements.

Mounting Options

Consider the available space and mounting requirements of your application. Different actuators offer various mounting options such as flange mounting, foot mounting, or pivot mounting. Choose an actuator that can be easily integrated into your system.

Environmental Conditions

Evaluate the environmental conditions in which the actuator will operate. Factors such as temperature, humidity, and exposure to dust or chemicals can impact the actuator's performance and durability. Ensure that the actuator is designed to withstand the specific conditions of your application.

Types of 90 Degree Pneumatic Rotary Actuators

There are several types of 90-degree pneumatic rotary actuators available in the market. Let's explore some common types:

Rack-and-Pinion Actuators

Rack-and-pinion actuators use a piston-driven rack that engages with a pinion gear to generate rotary motion. They offer high torque and precise control, making them suitable for applications requiring heavy loads and accurate positioning.

Vane Actuators

Vane actuators utilize a rotating vane inside a cylindrical chamber to convert linear motion into rotary motion. They are known for their compact size, lightweight construction, and high-speed capabilities. Vane actuators are commonly used in applications where space is limited.

Helical-Spline Actuators

Helical-spline actuators use a helical groove and spline shaft to convert linear motion into rotational movement. They provide high torque output and can handle heavy loads. Helical-spline actuators are often chosen for applications that require both high torque and precise positioning.

Scotch Yoke Actuators

Scotch yoke actuators use a sliding yoke and a crank mechanism to generate rotary motion. They offer high torque output and are suitable for applications that require high force and power. Scotch yoke actuators are commonly used in heavy-duty industrial applications.

Assessing Application Requirements

To choose the right 90-degree pneumatic rotary actuator, it is essential to assess your application requirements thoroughly. Consider the specific needs of your system, such as load characteristics, motion control requirements, and environmental conditions. Take into account factors like the required torque, speed, and mounting options.

Selecting the Right Actuator for Your Application

Based on the assessment of your application requirements, you can now select the appropriate 90-degree pneumatic rotary actuator. Consult with actuator manufacturers or suppliers who can provide expert advice based on their experience and knowledge. Consider factors such as actuator performance, reliability, and cost-effectiveness.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential for the optimal performance and longevity of your 90-degree pneumatic rotary actuator. Follow the manufacturer's guidelines for installation and ensure that the actuator is correctly mounted and aligned. Regularly inspect and clean the actuator, and promptly address any signs of wear or damage.

Conclusion

Choosing the right 90-degree pneumatic rotary actuator is crucial for achieving efficient and reliable performance in your application. Consider factors such as operating pressure, torque output, rotation speed, mounting options, and environmental conditions. Assess your application requirements thoroughly and consult with experts to make an informed decision. With the right actuator in place, you can enhance productivity, precision, and automation in your system.

This article actually makes a lot of sense. I never realized how many little details go into picking the right actuator, stuff like torque and mounting options really matter more than people think. Its similar to how we choose apps or tools online too. Like with instatroif, it’s made for people who wanna check out Instagram stuff without being seen or tracked. Sometimes you just want to explore quietly, you know? Same idea with picking the right tech. It’s all about finding what fits how you like to work.