Ball Valves: How Do They Work?

- Aira Euro Automation

- Feb 25, 2022

- 4 min read

A port, otherwise called a drag, is arranged in the focal point of the ball. In the event that this focal port is situated up in a similar course as the appended pipeline, the ball valve is in the vacant position, permitting liquid or gas to move through. Whenever the port becomes opposite to the stream bearing, the ball valve closes, obstructing the stream way and preventing any fluids from going through.

Although most standard ball valves have exceptional stop estimates that just take into consideration a 90-degree turn, a couple considers total 360-degree revolution. While a 90-degree pivot is hypothetically everything necessary for ball valves to open and close, there are a few applications where the total development of the center is best. In light of its powerful and impermeable fixing when shut, the ball valve is a typical modern choice. This makes them particularly appropriate to ventures moving perilous synthetic compounds or gases, for example, petroleum gas, which requires a protected and quick shutoff. Be that as it may, they ought not to be utilized in choking-like applications where the seats' respectability can be imperiled by steady wear.

1. Trunnion Mounted Ball Valve - This type of ball valve has an extra mechanical mooring component at the top and base, making it more appropriate for use in high-pressure applications. Since the contained trunnion-mounted stem retains any extra push or tension from the pipeline, it keeps pointless pressure from influencing activities and shortening working life.

2. Drifting Ball Valve - It comes up short on the trunnion's extra steading part and is rather simply connected to the stem. These ball valves get their name on the grounds that the ball drifts downstream of the stream, squeezing in the inconsistency of the seat to make its seal.

3. Rising Ball Valve - This kind of ball valve utilizes a slant and-go system to limit seal scouring, one of the most widely recognized reasons for untimely valve disappointment. The center wedges against the valve's seating for complete shutoff when the valve is gone to the shut position. The middle center slants from the seal when the valve is gone to the vacant position, permitting the fluid or gas stream to move equitably through.

What Are the Benefits of Using a Ball Valve?

Ball valves are a generally involved framework in an assortment of enterprises. Their direct yet reliable nature makes them a famous choice for private applications. Be that as it may, their financially savvy producing interaction and basic support make them ideal for business use.

Yet, before you feel free to mount these valves in your construction, you should dive deeper into how they work. Here is a summary of these valves' capacities and fundamental design to assist you with get-together this information.

Ball valves are very normal due to their lightweight and low-support nature, which doesn't need grease while as yet furnishing a snug seal with negligible force. While picking between all of the valve plan styles, ball valves are as well as most affordable decision.

The main downside of ball valves is that most plans have unfortunate choking qualities, effectively dissolving the valve seat. The trunnion has to some degree moderated this mounted ball valve plan, however, it should, in any case, be an element for those considering ball valves for applications requiring high choking.

Ball valves are likewise normal as a result of their capacity to function admirably in different applications and markets. Ball valves are normal in the oil and gas industry, but at the same time, they're utilized in numerous different ventures, including fabricating, compound capacity, and, surprisingly, private applications.

How does a ball valve function?

The ball valve's functioning instrument works as such overall. Assuming the valve is opened physically or by an actuator, some power is expected to turn the switch or handle a quarter turn. The power is moved to the stem, which opens the plate.

The emptied side of the ball plate faces the media stream as it pivots. The switch is opposite to the progression of media now, and the port is corresponding to the progression of media. Just a quarter-turn is permitted because of a handle stop close to the stem and hat interface.

The switch is turned around a quarter go to close the valve. The stem turns the ball plate the other way, forestalling the media stream. The switch is corresponding to the port, which is opposite.

Pay heed, nonetheless, that there are three distinct kinds of ball circle development. Each of these has its own arrangement of capacities.

The ball plate of the drifting ball valve is suspended from the stem. The ball plate part of the way trusts on the interior power for the tight seal ball valves are known since there is no insurance at the lower part of the ball.

As the valve shuts, the ball is pushed towards the measured downstream seat by the media's upstream direct strain. This expands the valve's fixing factor by giving positive valve snugness. Whenever the valve is shut, the inside pressure is conveyed by the drifting ball valve configuration's downstream seat.

The trunnion-mounted ball valve is one more type of ball plate plan. The ball plate is held consistent by a progression of trunnions at the lower part of the circle. Whenever the valve shuts, these trunnions assimilate the power from the strain load, diminishing contact between the ball circle and the seat. Both upstream and downstream ports are exposed to fixing strain.

Whenever the valve closes, spring-stacked seats push against the plate, which turns just in one heading. These springs immovably hold the seat to the ball. Balls mounted on trunnions are great for applications where high strain isn't expected to move the ball to the downstream seat.

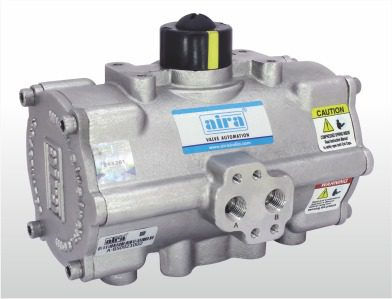

Aira Euro Automation is a Valve Manufacturer in Jordan. We offer Ball Valve, Butterfly Valve, Control Valve, and many other Valves in Jordan.

Comments