Proportional Solenoid Valve - How They Work

- Aira Euro Automation

- Apr 22, 2022

- 4 min read

A relative control valve is a valve used to control liquid stream rate by fluctuating the size of the stream entry using a restrictor. The directed stream rate, therefore, changes boundaries influencing a cycle in a framework, essentially level, tension, and temperature. The other minor boundaries include weight, thickness, dampness, thickness, Ph, variety, and consistency.

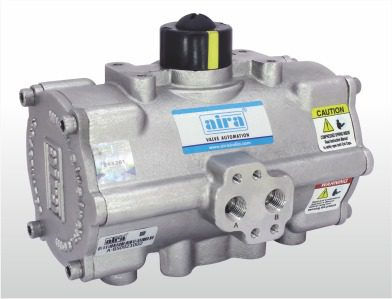

In a programmed control valve, the restrictor is coordinated by a sign from a regulator called an actuator. A relative control solenoid valve uses a solenoid as an actuator for variable valve situating.

A direct-worked 2-way standard relative solenoid valve works the same as a direct-worked solenoid valve with the distinction that the previous works through a scope of valve situating while the latter just gives two exchanging states (for example on/off), Figure 1. In a direct-worked relative solenoid valve, the unclogger is the restrictor.

Working Principle

On a basic level it is feasible to relatively control the unclogger with variable DC voltage, but practically speaking static grating on the aide points of the unclogger hinders the responsiveness of the valve, which brings about more noteworthy hysteresis impacts (the peculiarity wherein the worth of an actual property falls behind changes in the impact causing it). To forestall static rubbing, the typical delta sign can be changed over into a heartbeat width balanced voltage signal (PWM) utilizing extraordinary control gadgets.

Beat width adjustment (PWM) is a method frequently used to permit the control of the power provided to electrical gadgets. The typical worth of voltage (and current) taken care of to the solenoid is constrained by turning the power switch on and off at a quick rate (Figure 2). This sort of control places the unclogger into an extremely quick but feeble abundance wavering. The swaying places the unclogger in a reasonable state which keeps up with its steady sliding grating. The unclogger's swaying movement meaningfully affects the liquid's stream conduct.

The more extended the switch is on contrasted with the off periods, the higher the complete power provided to the solenoid. The term obligation cycle portrays the extent of on schedule, t1, to the cycle length, T. A low obligation cycle compares to low power because the power is off more often than not. The obligation cycle is communicated in percent, 100 percent being completely on.

In an ordinarily shut solenoid control valve, with no ongoing taken care of to the loop, the spring pushes the unclogger downwards to a completely shut position, in this way the valve is kept up close. Applying current to the curl produces an attractive field to move the unclogger up against the bring spring back. At the 100 percent obligation cycle, power is completely taken care of to the solenoid and the valve is kept up with open. Obligation cycles between 0 to 100% territory relatively change the progression of the valve. For instance, an obligation pattern of half taken care of to the solenoid moves the spring and the unclogger to half of the working reach.

Selection Criteria

In Continuous stream applications, the decision of proper valve size is considerably more significant than with on/off valves. With a high hole setting the valve can as of now arrive at full stream rate at a tiny opening (stroke). The excess stroke is then futile, which disables the goal and the general control nature of the valve. With a hole size that is too little then again, the valve won't arrive at full stream rate. It is suggested that the strain drop over the valve ought to associate with 30 % of the absolute tension drop inside the framework.

For right and exact control working, solenoid control valves should be arranged and chosen for their unique reason. The main boundaries for choosing a solenoid control valve are the kV esteem (given in m3/h) and the application's strain range. The lower the valve's opening or the more grounded the curl, the higher the strain the valve can shut down. The most elevated kV esteem required is determined because of estimating equations in Figure 3.

Because of the determined kV esteem and the tension scope of the arranged application, a correspondingly fitting valve type and its expected hole are not set in stone. Kindly note that the valve's kVs ought to be more prominent than the application's kV preferably by around 10 %.

Other choice rules to be considered are most extreme working strain, media (liquid), power utilization, the similarity of materials, reaction time, media temperature, working voltage, and port association to name a couple. For more data concerning these determination standards kindly allude to this article or the manufacturer's datasheet for the particular item.

Typical Applications

Here are a few normal utilizations of the Proportional Solenoid Control Valve.

Burner/Flame Control: Two gases should be controlled in a burner control framework; both are in an ideal proportion with each other. The proportion of burning gas to oxidant gas, e. g., air or, still up in the air by the fire is expected for the separate cycle.

Level Control with Pressurization (Flow Pressure Control): Atmospheric strain control is one potential sort of level control. Using two solenoid control valves, a PID regulator supplies sufficient air or nitrogen so there is generally a similar strain squeezing against the liquid that changes when the liquid tension drops through eliminating a piece of the liquid.

Combination of Cold and Warm Water: A Pt100 temperature sensor estimates the temperature of the blended water. The temperature regulator carries this temperature to the given reference esteem by controlling two solenoid control valves likewise.

Aira Euro Automation is the leading valve manufacturer in India. We offer industrial valves like ball valves, butterfly valves, solenoid valves, plug valves, and many products.

Comments