THE BASICS OF INDUSTRIAL PIPING SYSTEM VALVES

- Aira Euro Automation

- Jul 30, 2022

- 4 min read

In an industrial framework and any piping framework, valves are utilized to limit, stop or control the progression of liquid. All the more explicitly, a few industrial valves are utilized to:

Control the cooling paces of water through cooling lines to manage the temperature.

Deal with the progression of concentrated acids or bases flowing through a line.

Divert stream starts with one line and then onto the next at a three-way valve.

Confine stream for framework balancing.

Forestall switch stream (really look at valves).

Naturally, stop the stream in case of a framework disappointment.

While considering accessible valves for an industrial framework, assessment relies upon both the present moment and long haul execution of a valve. Furthermore, depending on the application, one valve might beat another and offer an unrivaled support life. We are the leading valve manufacturer in Nigeria.

Kinds of Valves

Each engineer might have their inclination for a kind of valve, yet great engineering rehearses regularly direct which type is utilized given the motivation behind the valve. No matter what the final choice, the decision is much of the time in light of a few elements, including the:

Sort of administration or medium (fluid, slurry, and so forth.).

Anticipated recurrence of activity.

Size of the line.

Cost of proprietorship (includes how frequently should maintenance is expected for the seats and o-rings)

Financial plan of the venture.

For any situation, the main choices for industrial piping frameworks:

Ball valve. The most widely recognized valve utilized for the liquid stream, the ball valve, comprises a circle with an empty circular opening in the focal point of the pipeline. At the point when in the on position, the opening in the circle is predictable with the line. In the off position, the ball turns 90 degrees and stops the stream.

Gate valve. Think of a door valve (otherwise called a guillotine valve) like a middle age palace entryway that drops straight out of control using a level face, vertical circle, or entryway. The

Check valve. is a general help valve utilized principally for on/off, non-throttling administration and is most utilized where the recurrence of purpose is low.

Take a look at the valve. Most industrial offices install check valves because of the risk survey process, as it permits liquid to move through it in only one heading. It remains open as the stream continues forward, yet closes if the stream stops or switches. The moving part for a check valve might be a plate, stem, hinge pin, spring, ball, or something else.

Butterfly valve. Not at all like a few different valves, butterfly valves can restrict or manage the stream without totally restricting it. In a butterfly valve, a plate pivots clockwise or counter-clockwise to allow or confine the stream (like the ball valve). Depending on the ideal stream rate or speed, the plate can be halted opposite the stream, lined up with it, or in someplace in between. Two normal varieties include a wafer valve and a drag valve. As a general rule, butterfly valves are more affordable and have a more modest footprint in the framework, however, make more strain drop or stream limitation than other valve choices recorded.

Stomach valve. In this valve, a stomach brings and raises down to limit or allow stream. These are great when the liquid being moved contains suspended solids. Furthermore, these valves are more exact for controlling the stream volume than numerous other options, however, will quite often come at a greater cost.

Different sorts of valves might be utilized for applications other than those recorded previously. Most materials work with various valves, and plants use them contrastingly depending on their insight.

Instructions to Evaluate Valves

Since a framework depends on valves to control the stream and frequently limits it amid hardship, valve choice is urgent. With many kinds, materials, manufacturers, and models to browse, begin by assessing each based on effortlessness, productivity, and security.

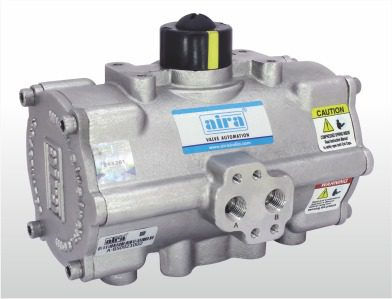

Aira Euro Automation is the leading valve supplier in Nigeria. We offer various types of industrial valves like ball valves, butterfly valves, control valves, pressure reducing valves, and many more.

Effortlessness

Set forth plainly, when a valve needs to open, it ought to handily open — or the other way around. While this single capability might appear to be basic, it isn't as direct in industrial plants.

Sadly, because of various elements — including erosion, rust, and dampness collection — valves can stall out.

Whether the valve is mechanized or manual, it ought to work precisely as intended for quite a long time. Very much like some other parts of the piping framework, the normal assistance life of the valve is basic to the framework's presentation. At the point when a valve becomes inoperable, it causes exorbitant margin time and fixes.

While considering different valve types and materials, pick the valve that will most reliably and flawlessly take care of its business, regardless of whether it was to remain unused for quite a long time.

Security

Regardless of anything else, maintaining security is a valve's major job. On the off chance that one release or sticks, various issues can emerge:

In the case of feeding response, the response science can be modified or continue longer than needed.

If a valve doesn't as expected close a tank while disconnecting the line from the tank, a monstrous break happens.

If an inadvertent stream inversion happens, a check valve is the main line of guard.

If a disappointment happens downstream, a valve should draw in to forestall further spillage and limit openness to the substance being conveyed.

An inoperable valve may unintentionally permit two synthetic compounds to blend, which can frequently become unsafe in an industrial plant.

For each situation, depending on the lines' items, a hole can cause risky circumstances for laborers in the type of a dangerous spill or airborne toxins. Moreover, inadvertent combinations or compound focuses may make perilous side effects or speed up wear on the line.

Comments