The Best Valves Manufacturers of India: A Comprehensive Guide

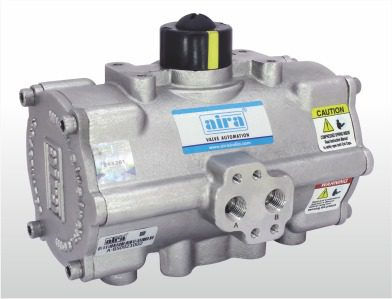

- Aira Euro Automation

- Feb 18, 2023

- 5 min read

If you need a valve manufacturer, you'll want to make sure you choose the best. But with so many options, how do you know which is right for you?

This comprehensive guide will tell you everything you need to know about choosing the best valve manufacturer in India. We'll cover what valves are, the different types, and why selecting a reputable manufacturer is essential. Plus, we'll give you tips on choosing the best valve manufacturer.

So whether you're in the market for a new valve manufacturer or want to learn more about them, read on for the ultimate guide.

Introduction

Many different types of valves are available on the market, each with unique features and benefits. But when it comes to finding the best valve manufacturers in India, it can be a challenging task.

With so many options, knowing what to look for in a reputable manufacturer is essential. This comprehensive guide will provide you with everything you need to know about finding the best valve manufacturers in India, including what to look for in a reputable manufacturer and the top manufacturers in the country.

What are valves?

A valve is a device that controls the flow of fluids (liquid, gas, or slurries) by opening or closing passages. Valves are classified into different types based on their function, structure, and operating principle. The most common types of valves used in industrial applications are gate valves, globe valves, ball valves, butterfly valves, and plug valves.

Valves are used in various industries such as oil and gas, power generation, water and wastewater treatment, chemical processing, food and beverage processing, and more. They are an essential part of many process systems as they help regulate and control fluid flow.

Gate valves are the most common type of valve used in industrial applications. They are named for their function - open and close like a gate to control fluid flow. Gate valves can be either manual or automatic.

Globe valves are another type of valve used in industrial applications. They get their name from their shape - they have a round body with a globe-shaped disc that opens and closes to control fluid flow. Globe valves can also be either manual or automatic.

Ball valves are another type of valve used in industrial applications. They get their name from their shape - they have a round body with a ball-shaped disc that opens and closes to control fluid flow. Ball valves can also be either manual or automatic.

Butterfly valves are yet another type of valve used in industrial applications. They get their name from their shape - they have a round body with a butterfly-shaped disc that opens and closes to control fluid flow. Butterfly valves can also be either manual or automatic.

Last but not least, plug valves are another type of valve used in industrial applications. They get their name from their shape - they have a cylindrical body with a plug-shaped disc that opens and closes to control fluid flow. Plug valves can also be either manual or automatic.

Different types of valves

There are different types of valves based on their function, structure, and operating principle. The most common types of valves used in industrial applications are gate valves, globe valves, ball valves, butterfly valves, and plug valves.

Gate valves are one of the most common valves used in industrial applications. They are named for their gate-like mechanism that opens and closes to control fluid flow. Gate valves are classified into two main types: rising stem and non-rising stem. Rising stem gate valves have a branch that grows as the gate is opened, while non-rising stem gate valves have a stem that remains stationary as the gate is opened.

Globe valves are another common type of valve used in industrial applications. They are named for their globe-shaped body containing a movable disk or plug that controls fluid flow. Globe valves can be classified into two main types: linear motion and rotary motion. Linear motion globe valves have a plug that moves in a linear path as it opens and closes, while rotary motion globe valves have a pin that rotates as it opens and closes.

Ball valves are also standard in industrial applications. They get their name from their ball-shaped disk that controls fluid flow. Ball valves can be classified into three main types: floating ball, trunnion mounted ball, and vented ball. Floating ball valves have a disk that floats on top of the fluid to seal it off, while trunnion-mounted ball valves have a disk attached to a shaft at both ends so it can rotate to open and close the valve. Vented ball valves have a hole drilled through the center of the disk so that fluid can pass through even when the valve is closed.

Butterfly valves are named for their butterfly-shaped disks that control fluid flow. They are classified into two main types: lug type and wafer type. Lug-type butterfly valves have disks with lugs or handles that protrude from the sides so they can be turned to open and close the valve. In contrast, wafer-type butterfly valves have disks with handles that are flush with the valve's body so they can be turned to open and close the valve without protruding from the sides.

Plug valves get their name from their plug-shaped mechanism that controls fluid flow by opening or closing passages within the valve's body. Plug Valves can be classified into three main types: lift check, swing check, and piston check. Lift check plugs have a disk that lifts to open or seal off passages, swing check plugs have a disk that turns open or shut like a door to control passageways, and piston check plugs use a piston to push up or pull down a sleeve to cover or uncover an opening through which fluid can flow.

Why is it important to choose the best valve manufacturer?

Valves are essential to many industrial applications, and choosing a reputable and reliable valves manufacturer is crucial. There are a few things to consider when selecting a valve manufacturer, such as their experience, quality of products, and customer service.

It is essential to choose a valve manufacturer with a lot of experience in the industry. This ensures that they have the knowledge and expertise to produce high-quality products. A reputable manufacturer will also have ISO 9001 certification, which indicates that their products meet international quality standards.

When choosing a valves manufacturers of India, it is also essential to consider the quality of their products. The manufacturing process should be done in clean conditions using high-quality materials. The finished product should be tested to meet all the required specifications.

Finally, choosing a valve manufacturer with good customer service is essential. This means that they should be responsive to inquiries and able to provide technical support if needed. A good customer service team will make sure that your experience with the company is positive from start to finish.

How to choose the best valve manufacturer in India?

When choosing a valve manufacturer in India, there are several factors to consider. The most important factor is experience. A reputable and experienced manufacturer will understand the different types of valves and the manufacturing process. They can provide high-quality products that meet all the required specifications. Another essential factor to consider is the quality of materials used in the manufacturing process. The finished product should be made from high-quality materials that are durable and long-lasting. The manufacturing process should also be done in clean conditions to ensure that the finished product is of the highest quality. The company should also have a good customer service team to ensure that your experience with them is positive from start to finish.

Some of the best valves manufacturers in India

There are many reputable and experienced valve manufacturers in India that can provide high-quality products that meet all the required specifications. These manufacturers include Jyoti Valves, Fluid Controls, and SVF Flow Controls. These companies have years of experience in the industry and use high-quality materials to manufacture their products. They also have good customer service teams to ensure your experience with them is positive from start to finish.

Comments