Triple Offset Valves - Some Advantages and Considerations

- Aira Euro Automation

- Sep 2, 2022

- 3 min read

Industrial cycle control now and again involves the control of fluid streams, ranging from slurries or oil to extraordinarily refined liquids and gases. The gigantic collection of purpose specifics has prompted numerous valves with execution characteristics to match those necessities. One typical valve type is the butterfly valve. In its most direct design, it is a plate arranged in the method of the fluid stream that is related to a shaft. The plate turns through a 90-degree curve to introduce either its face (valve shut) or its edge (valve open) to the fluid stream way. I clarified certain advantages and hindrances of butterflies a while earlier under the title "Is a Butterfly Valve Right for Your Application?".

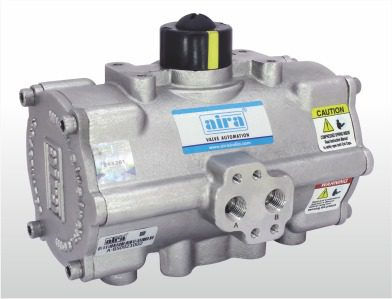

Aira Euro Automation is the leading valve manufacturer in Ghana. We offer various types of industrial valves like ball valves, butterfly valves, control valves, plug valves, and many more.

There is a variety of essential version of the butterfly valve that gives distinct advantages to various applications. Suggested to some degree officially as a triple offset butterfly valve, it can in like manner be even more regularly called fundamentally a triple offset valve.

How is a triple-adjusted butterfly valve not exactly equivalent to a central butterfly valve?

The triple offset valve disposes of the determined game plan of the shaft and circle, using instead a shaft mounting blueprint that moves the shaft to turn off both the point of convergence of the plate and the point of convergence of the drag. This shaft positioning, while simultaneously creating a greater stream obstruction in the empty position, sets the plate improvement way in the genuine plan to take advantage of the third offset, which is the sealing surface. Triple offset valves have a startling seal in contrast with other butterfly valve varieties. There is an exact sealing surface, the point of which is determined by sectioning an imaginary right point cone shape that loosens up along the drag. In any case, the culmination of the cone doesn't lie on the point of convergence of the drag. This inclination of the seal cone is the third offset. You can see a portrayal of this depiction in the report included underneath.

What advantages might those distinctions at some point bring to your application?

Triple offset valves have plates that don't contact the sealing surface until the valve is closed. This is instead of other butterfly valve plans, which have contact between the circle and adaptable seals for part or all of the plate travel, close by the connected grating and wear.

Elastomer or other equivalently flexible materials are not supposed to give a zero-spillage, bubble-tight shutoff. Sealing is overall developed with metal-to-metal contact.

Contact-free stroking of the valve circle. Actuator power necessities may be diminished.

All metal improvement gives parts of disintegration and intensity deterrent not found in other butterfly valve plans with flexible seals.

This valve is force-fixed, not position-fixed like other butterfly varieties. Actuator force drives the characteristic of the machined metal surfaces to make a tight shutoff.

No breakaway power is essential, since the plate isn't an area of strength for contacting.

The seating strategy prevents over-stroking of the valve, a potential issue with other butterfly valves.

Different manufacturers could have marginally exceptional capacities, yet this should help you with considering the upsides of this butterfly valve variety. Despite how its initial cost may be higher, the typical lower maintenance essential, longer assistance life, and better execution may be legitimate. Speak with a valve thing master about your application. I've made generally that combining your interaction dominance with the uncommon thing information on a specialist bargains engineer will convey a positive outcome.

Comments