Valve Automation in India: Everything You Need to Know

- Aira Euro Automation

- Mar 3, 2023

- 3 min read

Valve automation is essential in many industries but is especially critical in India. Automating valves has many benefits, including increased efficiency and safety. Automated valves can be used in various applications and customized to meet your business's specific needs. If you are considering automating your valves, this blog post will give you everything you need to know.

Why is valve automation critical in India?

Valve automation is essential in India for several reasons:

It can help to improve the efficiency of various industrial processes.

It can help to improve safety in industrial settings.

It can help reduce manufacturing costs and operate industrial facilities.

Valve automation can help improve the quality of products and services produced by the Indian industry.

What are the benefits of automated valves?

Automated valves can offer several benefits in various industries, including the oil and gas, chemical, power generation, food and beverage, and pulp and paper sectors.

Some of the advantages of automated valves include the following:

- Reduced downtime and increased efficiency: Automated valves can help reduce downtime by ensuring the process runs smoothly and efficiently. In addition, they can also help to improve process control and reduce the need for manual intervention.

- Improved safety: Automated valves can help to improve safety by reducing the potential for human error. They can also help to prevent accidents by providing a physical barrier between the operator and the process.

- Cost savings: Automated valves can provide significant cost savings by reducing the need for skilled labour. In addition, they can also help to reduce maintenance costs and improve process uptime.

How do automated valves work?

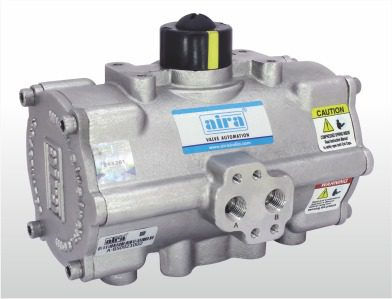

Automated valves use various methods to open and close, depending on the type of valve and the application. The most common types of actuators are pneumatic, hydraulic and electric.

Pneumatic actuators use compressed air to move the valve stem. When the air pressure is released, a spring returns the valve to its default position. Pneumatic actuators, such as HVAC systems, are often used in applications where speed is less critical than repeatability.

Hydraulic actuators use fluids, usually oil or water, to move the valve stem. When the fluid pressure is released, a spring returns the valve to its default position. Hydraulic actuators are often used in applications where speed is essential, such as in oil and gas pipelines.

Electric actuators use electric motors to move the valve stem. When power is turned off, a spring returns the valve to its default position. Electric actuators are often used when precise control is essential, such as in chemical plants.

What types of valves can be automated?

Several different types of valves can be automated, including ball valves, butterfly valves, check valves, diaphragm valves, gate valves, globe valves, and pinch valves. Ball valves are often used in applications requiring a tight seal, such as in the food and beverage industry. Butterfly valves are often used in applications requiring a significant flow rate, such as in the oil and gas industry. Check valves are often used in applications where backflow must be prevented, such as in the water treatment industry. Diaphragm valves are often used in applications requiring a clean or sterile environment, such as in the pharmaceutical industry. Gate valves are often used in applications requiring a high degree of control, such as in the power generation industry. Globe valves are often used in applications requiring a significant flow rate, such as in the chemical processing industry. Pinch valves, such as semiconductors, are often used in applications requiring a precise flow rate.

Why automate your valves?

There are many reasons why you should automate your valves. One reason is that automated valves can offer more efficiency than manual valves. Mechanical valves can also provide safety advantages and cost savings.

Another reason to automate your valves is that they offer increased safety compared to manual valves. Automated valves can help prevent accidents by automatically shutting off or redirecting flow in case of a leak or other problem. This can help to protect workers and equipment from harm.

A third reason to automate your valves is that they can offer cost savings compared to manual valves. Automated valves can help to reduce downtime by automatically opening and closing as needed. This can help to save on labour costs associated with manually opening and closing valves. In addition, automated valves can help improve process control, leading to improved product quality and reduced scrap rates.

How to get started with valve automation

You can take a few steps to get started with valve automation in India. First, you need to determine what type of actuator you need. Pneumatic, hydraulic, or electric? Second, you need to determine what type of valves you need. Ball, butterfly, check, diaphragm, gate, globe, or pinch? Third, you need to select the reason for automating your valves. Is it for increased efficiency? Safety advantages? Cost savings? Once you have answers to these questions, you can begin researching suppliers and prices. When selecting a supplier, consider quality, delivery time, and cost factors.

Comments